Introduction

|

|||||||||

|

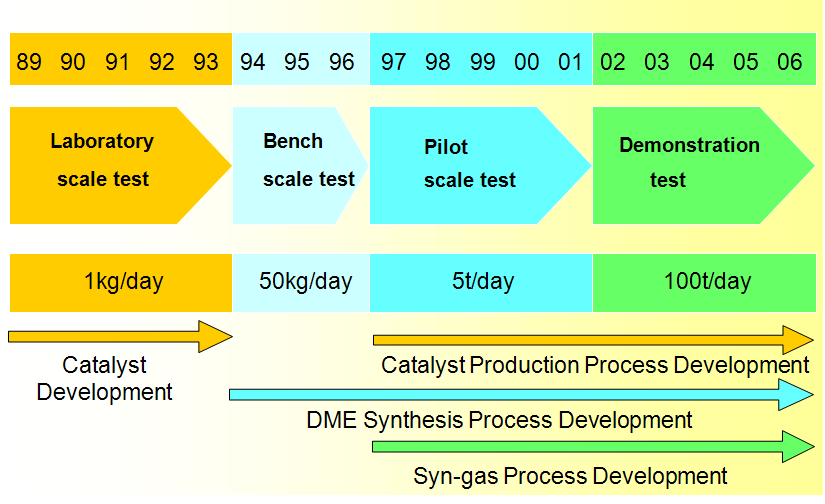

Development of slurry phase Direct DME synthesis process and Transfer of the technology to RenFuD • Slurry phase Direct DME synthesis process had been developed by NKK (now JFE), stepwise starting from beaker scale, through bench scale, to 5 ton/day pilot plant with its own proprietary catalyst since 1989. •From 2002 to 2007, 100 ton/day demonstration plant project was successfully conducted by DME Development Corp. funded by 10 companies. The process performance, catalyst life and long-term stable operation have been demonstrated for a commercial scale technology. With this technical success, feasibility studies of commercial scale DME production from natural gas or coal were conducted. • Total, JAPEX, INPEX and Toyota Tsusho, former members of DME Development Corp., succeeded the technology in 2010. • In 2016, those four companies have transferred the technology patents to RenFuD Corporation. RenFud is now ready for licensing of the DME synthesis process technology with its own technical know-how and supplying its proprietary catalyst.

Recent presentations on DME (Dimethyl Ether) ・Sep-2016, ”Bio-DME Production using Modular Slurry Phase DME Synthesis Process”,7th International DME Conference, Houston, USA [.pdf] ・Aug-2016, ”DME energy system produced from lignite derived gas and renewable hydrogen ”, Annual Conference of Japan Institute of Energy, [.pdf] ・Oct-2015, ”DME production from Oxygen blast furnace gas”, 9th Asian DME Conference, Wuzhen, China[.pdf] ・Nov-2013, ”DME Actvities in Japan”, 8th Asian DME Conference, Jakarta, Indonesia [.pdf] ・Aug-2013, ”DME as a carrier of Renewable Energy”, Annual Conference of Japan Institute of Energy [.pdf] ・Nov-2011, ”DME in Japan-Perspective in New Paradigm after Fukushima-”, 7th Asian DME Conference, Niigata, Japan [.pdf] ・Sept-2009, ”DME Production Process from Coal & Biomass”,6th Asian DME Conference, Seoul, Korea [.pdf] ・Mar-2008, ”New Clean Fuel DME”, Dewitt Asia Pacific Global Methanol & MTBE Conference, Hochiminh, Vietnam [.pdf]

|

| top | next » |

Japanese

Japanese English |

English |